Asics and multinational software development company Dassault Systèmes have jointly opened a test studio near Paris to trial a new service that offers on-demand personalized insoles for consumers’ foot shapes.

The new ”Asics Personalization Studio” is an ultra-compact factory on the site of Dassault Systèmes’ headquarters in Vélizy-Villacoublay. The modular structure combines Dassault Systèmes’ 3D Experience platform and virtual twin technology with Asics’ proprietary sports technology to enable on-demand, on-site manufacturing of footwear parts that meet each user’s exact specifications.

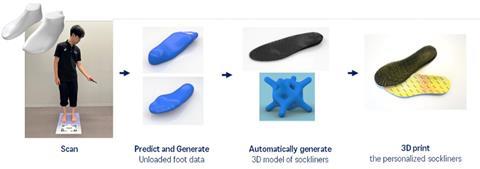

Based on the user’s foot shape data and preferences, Asics will use Dassault Systèmes’ modeling and simulation technology and its own knowledge of sports and physical movement to algorithmically predict the appropriate shape of the insole. The insole is then produced using advanced 3D printing technology. This is a thick lattice structure made from a highly flexible material that is layered to provide excellent breathability and softness. The exact degree of softness can be varied for each part of the foot, promoting physical recovery by reducing strain while improving performance.

Asics plans to conduct functional tests and monitor user satisfaction as part of a trial run for a wider market launch. From 2025, the Asics Personalization Studio will be relocated to Japan for further testing, and the company will consider applying the technology to footwear products other than insoles in the future.

Asics and Dassault Systèmes entered a strategic partnership in 2023 and are working together to bring new customer experiences and sustainable value to the market. This project is one of the key initiatives to accelerate Asics’ Vision2030, which aims to create a world where we can all live healthy lives, both mentally and physically, and maintain our commitment to exercise and sport. This includes a future where shoes are personalized according to each individual’s foot shape and needs.