Karl Mayer is seeing strong momentum in India’s textile sector as manufacturers scale warp knitting capacity to meet rising demand in sportswear, footwear and technical textiles. The company reported record engagement from Indian clients at ITMA Asia 2025, confirming the market’s shift toward high-productivity technologies.

Karl Mayer said it is experiencing “exceptional” interest from Indian manufacturers as the country accelerates investment in warp knitting technologies across apparel and technical textiles. India has become one of the fastest-growing markets for warp knitting as mills upgrade capacity in response to rising domestic consumption and export opportunities.

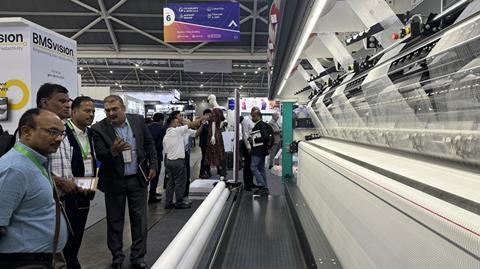

At ITMA Asia 2025, the company recorded its strongest-ever response from Indian visitors. In a statement shared through Fibre2Fashion, Karl Mayer noted particular demand for tricot and raschel machines used to produce performance fabrics for sportswear, athleisure and footwear. The company’s local subsidiary also reported increased orders for equipment supporting technical applications, including nets, composite structures and protective textiles.

Expanding applications in sporting goods

Warp knitting—a high-speed textile production method that forms fabric by creating loops in a vertical direction using multiple parallel yarns—is playing an increasingly strategic role in the sporting goods industry:

Sportswear and activewear: Machines produce lightweight, breathable fabrics with high stretch and UV protection, widely used in functional apparel and hiking wear.

Footwear: Single-face fabrics, spacer textiles and engineered jacquards for shoe uppers are now mainstream in performance running and lifestyle footwear.

Swimwear: Hardwearing warp-knitted materials support durability and colorfastness for competitive and leisure swimwear.

Equipment: The technology is used in nets for stadiums and ski slopes as well as components for boards and protective gear.

Smart textiles: Karl Mayer’s research projects, including “DiMo – Digital Motion,” integrate conductive fibres directly into knitted structures, enabling wearables such as ECG monitoring shirts.

India’s warp knitting expansion strengthens sporting goods supply chains

India’s rapid rise in synthetic apparel and sportswear manufacturing is reshaping sourcing patterns. Domestic players such as TechnoSport already rely on Karl Mayer tricot machines for performance-oriented product lines, while export-focused mills see warp knitting as a route to higher margins and faster turnaround times.

For global sporting goods brands, the increased availability of advanced warp-knitted fabrics in India improves supply chain resilience and access to specialized materials. The expansion also indicates a shift from circular knits toward more technically capable structures that support differentiated product performance.

About Karl Mayer

Karl Mayer is a German manufacturer of textile machinery headquartered in Obertshausen, near Frankfurt. Founded in 1937, the company specializes in warp knitting and technical textile solutions, producing both tricot and raschel machines used across apparel, automotive, medical and technical textiles. Karl Mayer operates production facilities in Germany and China, and maintains a global sales and service network. The company is recognized as a technology leader in warp knitting, with ongoing investments in digitalization, automation and smart textile development. It regularly showcases innovations at major industry events including ITMA and maintains research partnerships focused on integrating electronics into knitted structures.