Repairs, resales, recycling and now refurbishment and “re-biking.” The cycling industry really is Re:Thinking Business. Munich-based Rebike Mobility GmbH is a prime example of how a more circular and sustainable way of doing business doesn’t have to compromise on success. What began just five years ago as an online marketplace for buying and selling second-hand premium e-bikes, today consists of business with two strong pillars: Subscription rentals and resale. At the heart of all this is refurbishment. Our bike industry specialist Jo Beckendorff explains more.

Together with its Refurbishment Center, which opened last year in Kempten, and an online digital resale platform, Rebike is not only one of the largest e-bike refurbishers in Germany but also a successful marketer of used and new e-bikes. Relative newcomers, the company was founded in 2018 by Thomas Bernik and Sven Erger. A background in IT means the company can utilize digitized and automized processes to a degree not yet common in the bicycle industry. In its own words: “As far as digitization and automation are concerned, we’ve built it up in a highly professional manner. That’s where we’re way ahead in the bike industry now.”

Rebike: An overarching business model which feeds into itself

Rebike’s 2019 subscription platform ebike-abo.de was designed to appeal to the average “Joe Cools” who want a big name bike but see the high purchase price of a branded e-bike as an obstacle to buying. “On the one hand, we are addressing the target group that has been looking for a practical alternative to buying a premium e-bike for some time. At the same time, we create an overarching cycle for our business model of refurbished bikes,” explains Rebike Co-founder and COO Erger.

Once the bike subscription period – 3, 6, 12 or 24 months – has expired, Rebike sells the refurbished e-bikes via their original platform rebike.com.

The startup has been lucky. “When our subscription platform went live, corona came along. Business went through the roof. No one wanted to get on public transportation anymore. That benefited us,” says Rebike Co-founder and CEO Bernik.

What has also helped is consumer’s rising awareness about the impact of their purchase and lifestyle choices. The CO2 emission savings between switching from a car to an ebike are easy to explain. But the impacts of buying a preowned and refurbished item are becoming better known too.

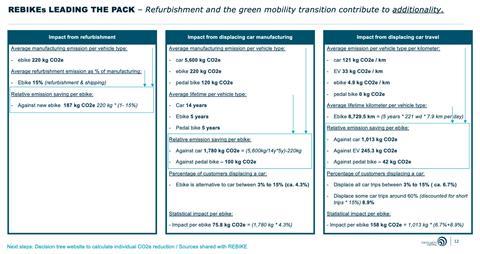

The manufacture of a new ebike has been calculated at 220 kg CO2e. To refurbish a bike uses just 15 percent of these manufacturing emissions, saving 187 kg CO2e.

A greener refurbishment process

With its high quality standards, the assembly and refurbishment process in Kempten, Germany is based on digitization and automation: “Every workstation has a PC. From sourcing to sales – we digitize every step,” Rebike explains.

Incoming used bikes are closely examined at the inbound check. Frame, motor numbers and so on are fed into the ERP system. The battery is checked and also whether all necessary software updates are installed. Ultimately, the bike and all its data are entered into the system under a number that can be used to track the bike to the end of its life.

Then it’s off to the fully automated bicycle washing machine, produced especially for Rebike. This replaces an initial hand wash. Depending on the degree of soiling, it cleans each bike in five to eight minutes. The wash is fed by a 3,000 liter rainwater tank. The dirty water does not run into the sewer system, but rather is cleaned in a second 3,000 liter tank populated by the company’s “little pets” (microbes) and, true to a circular economy, is reused.

Once the bikes are washed, they roll into the refurbishment assembly line. Rebike has a predetermined checklist to examine exactly what is no longer in optimal condition and in need of replacement. Afterwards, the refurbished bikes are taken by testers for a final test ride. They also evaluate every quirk and every scratch and enter them directly into the ERP system. This then calculates the final selling price and the refurbished bike is then offered on Rebike’s website.

Not a subscriber yet?

Dive deeper into the sporting goods industry with the latest insights and stories – straight to your inbox!

As a final step before resale, all bikes are sent to the fully-automated photo studio. Here, they are captured by two cameras, both from the side and from above, in 360-degree shots. Erger describes why: “On [our website] end-consumers can zoom in on every described quirk on the bike using the 360-degree images and take a close look. This is how we ensure transparency. The customer sees the bike online as he would see it in the store. We also send the detailed battery and motor readout report with the delivery.”

The only thing missing? Haptics. And who knows, with developments in digital technology, maybe this will one day be a possibility.

Resale looks set to grow and grow

It is exciting to see where the comparatively young company will be in the next five years. In general, Rebike is looking towards a rosy future – not only because of its professionally built digitalization and automation, but also because of the growing number of consumers interested in subscription and leasing business models and the fact that the business feeds back into itself. Most leaser opt for a new bike after two years. If businesses can resell these products at the end-of-lease period, it’s another revenue stream.

For this comparatively young leasing and subscription business, it’s just the beginning. A French-language Rebike site went live in the middle of last year. Other neighboring countries are to follow soon.

And as its own subscription business continues to grow in the coming years, so too will the supply of returns shift up rapidly.

-> Enjoyed this article? Find more of our circular economy content in our Re:Thinking Business special edition.