After 7 years of manufacturing wetsuits, British outdoor and cycling brand and retailer Alpkit has partnered with Circular Flow to recycle old wetsuits into new, reused products. As open-water swimming booms and consumers spend more money on outdoor sports, more neoprene ends up in the trash each year. 20,000 more tons, according to research done by Alpkit and Circular Flow.

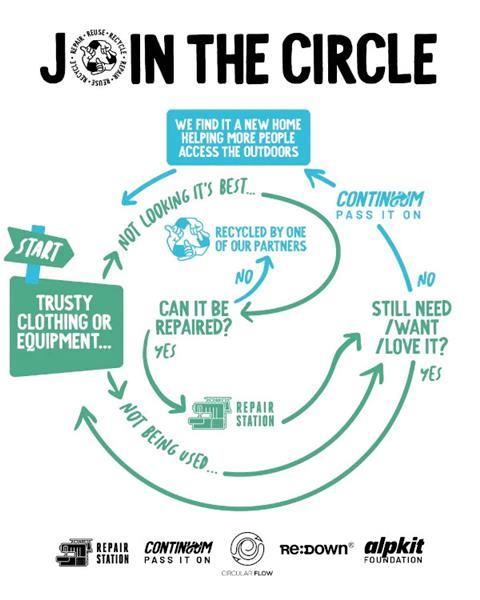

Sustainability is a core value for Alpkit (see the recent release of its latest sustainability report here) and a key component of their B Corp certification. For the brand, sustainability is not a collection of individual projects but a comprehensive way of working. It is a way of life. Alpkit has a repair station in each store where wetsuits can be repaired, reused or passed on as part of the Continuum Project. However, for the somewhat worn-out wetsuits, there was no clear initiative to recycle or reuse these products. Circular Flow has developed an effective and sustainable solution for recycling neoprene, the result of six years of development in collaboration with the University of Chemical Technology and Metallurgy in Bulgaria. This has led to the ability to combine shredded wetsuit particles into a stable and durable material. The company has expanded its process so that this material can be laminated to almost any textile material without the need for firing, melting or toxic chemicals. This greatly expands Circular Flow’s range of materials and products and provides another option for creating sustainable products.

Customers can drop off their wetsuits at one of Alpkit’s stores or send them to the brand via a free return service. The wetsuit is then sorted and sent to Circular Flow, where it is recycled into new neoprene. Alpkit’s goal is to process at least 1 ton of neoprene to help reduce waste.

Photo: Colin Davis on Unsplash