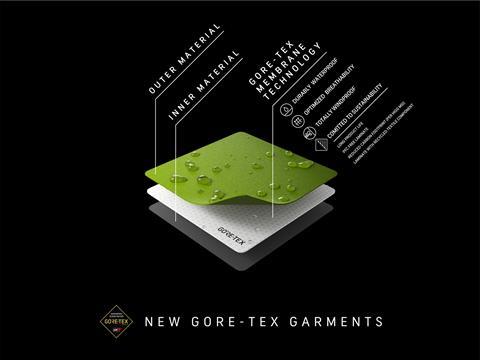

W. L. Gore & Associates has announced that the consumer unit of its Gore Fabrics Division will introduce the use of expanded polyethylene (ePE) as a new and more sustainable, complementary material platform that will serve as the basis for its future membrane technologies. The new ePE laminates (membrane and DWR treatments) are PFC-free and will be used in Gore-Tex brand consumer products starting with the autumn/winter 2022 collections. Among the first customers to use the ePE membrane in general outdoor and lifestyle apparel, lifestyle footwear and snowsports gloves are Adidas, Arc’teryx, Dakine, Patagonia, Reusch, Salomon and Ziener. With its features, Gore’s new ePE membrane contributes to the goals outlined in the Gore Fabrics Division’s “Sustainable Framework,” launched in 2020. Gore’s new ePE membrane is certified to conform with the Oeko-Tex® Standard 100 and is in the final stages of bluesign® approval. Laminates with the new ePE membrane will be available with recycled and spun-dyed outer and inner fabrics, among others. Gore claims that its new ePE membrane takes advantage of its high strength-to-weight ratio to create extremely lightweight and thin composites that are nonetheless mechanically robust, provide durable performance and a low environmental footprint. They can be combined with polyurethane (PU) to create a durably waterproof, windproof and breathable membrane. Combining the ePE material and low membrane mass results in a lower carbon footprint as measured by the Higg MSI index. The new membrane supports the Gore Fabrics Division’s goal of eliminating environmentally harmful PFCs (PFCEC) throughout the lifecycle of its consumer products.