After more than a decade, Swedish company Nano Textile Solutions now has a product ready for the market. Metamorfish, as they call the tech, is a fabric that makes almost everything custom-fit.

Remember the Spider-Man movies where Peter Parker, with a push of a button, gets his suit to fit snugly? That technology is now – almost – here. Swedish Nano Textile Solutions has developed a technology that allows materials to perfectly conform to the body in a minute. They call it Metamorfish, and earlier this year, the technology was demonstrated at the Gothenburg Horse Show. Together with Hööks, the company has created a riding boot utilizing the technology. Sam Issa, the brand’s founder and inventor, has a background in tailoring and has been developing the material for over ten years. Now, he wants the material to be used by more brands, feeling confident after a successful demonstration earlier this year that the company is ready to collaborate with more brands.

“We have developed a product together with Hööks and a manufacturer in Portugal. We have demonstrated the model to see market reactions, and it was incredibly positive. It was confirmed that this technology solves a big problem”, Issa said. “People struggle to find the right riding boots. They are too tight in the beginning. Almost cutting off circulation. But you don’t dare to buy them too big. You know, everyone has different calf sizes, which means as a manufacturer, you need to produce many variations, and stores have to stockpile and tie up capital. With our product, production decreases, which is our main target. Our product also allows retailers to reduce the variety of stock. This increases inventory turnover and ties up less capital while guaranteeing personalized precision for the end customer.”

Technology for customization Metamorfish explained

Can you explain the technology and how it works?

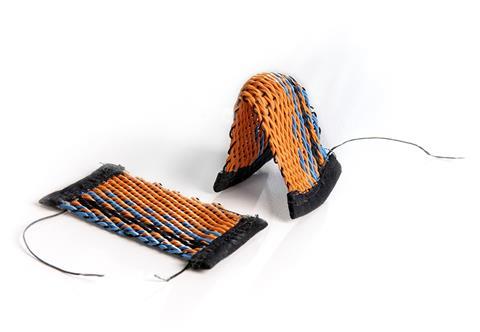

“The technology is based on components sewn into the garment that can expand the fabric up to 100 percent using electrical current. In practice, this means that with the push of a button, the size adjusts to the individual, a size that can be adjusted repeatedly hundreds of times. In a riding boot, you can shape the shaft to fit the calf perfectly. One minute after heating, the material molds to the body and maintains that shape despite still being flexible.”

Now you’re starting with riding boots, but technically, it could be applied to any product?

“It’s very universal. It can be integrated into anything. It can be pants or caps to achieve precision. All bodies are different and constantly changing in shape. You eat a little Christmas food, you know what happens. You run a marathon, you know what happens. The body is constantly changing, but the sizes of your products are fixed. What we’re doing here is that we can start with multi-sizing tech, as we call it.”

Custom-fit technology is for all materials

And does it work for all materials?

“Yes, it does. The product isn’t active when you use it, so it doesn’t need power after activation. This allows you to wash the products and jump into water if you want. It doesn’t affect them. And the technology works for all fabrics.”

What has the interest been like from brands you’ve talked to so far?

“Very high. Now people are starting to understand what we’re doing. When people understand, it’s like the penny drops. Initially, we tried to talk to brands about it, but everyone saw it as science fiction. But seeing is believing, and now that we have proof of concept, we can show that the products are tailored to the body and completely personalized. It’s like having made-to-measure.”

What’s realistic for a customer then in terms of a price increase with this technology? Will it be a much more expensive product because you’re using your technology?

“It will be an increase, of course, but it’s not that bad. Brands will decide how much of a markup they want to add. But we’re not talking about more than €50 to €100. Many already spend several thousand on equipment, and that’s something important to add. Where price sensitivity is lowest, that’s where we should be.”

Nano Textile Solution works as ingredient brand

So you’ll be in products where the end consumer is ready to pay a little more.

“We’re a lot like Mips. If you buy a Mips helmet, it’s obviously more expensive. And why are you willing to pay for that? Well, because you have a special feature, and that’s exactly the same logic we have. If you want precision fit, it costs a little extra, but we’re not talking about thousands.”

What’s your production capacity like?

“I’ve studied fashion and textile design, so I have expertise in this industry, from craftsmanship to industrial production. So that’s a success factor for us, that I’ve understood from day one that you can’t force changes in the production process. Our product is a memory thread that can be activated. This product can be sewn straight through, so everything is adapted to traditional production methods. We weave the material in Sweden on looms that we own. We’re in the process of installing an industrial loom now so that we can reach half a million units per year. It’s quite a lot, but it’s just one machine. We have five more waiting to be activated.”

Nano Textile Solutions wants to become a leader in smart textiles

The feeling is that you’re ready for the market.

“Absolutely. This is the dream. I’ve been working for 10 years to get to where we are today. We’re really in the sweet spot now, and we’re proving the technology in a market vertical within footwear. Then we’ll activate several such verticals within sports and other areas. And then maybe we’re talking about footwear, but also protection equipment and products within outdoor sports. But we also need to be careful about how many balls we should have in the air to be able to handle it in a quality way.”

You said it took you ten years to get here. Where are you in 10 years, in 2034?

“That’s too long to speculate, but the vision is that we become leaders in smart textiles. Hopefully, we’re a unicorn; that’s absolutely the dream. You really need to be passionate, excuse the expression, an idiot to be able to endure this long.”

In the end, it might be that brands reach out and ask to use the technology rather than the other way around. Like Gore or Mips.

“That’s absolutely a model we’re looking at.”