A newly published academic review examines four decades of smart textile development, from early synthetic fabrics to today’s sensor-embedded garments that monitor heart rate, body temperature, and muscle activity while athletes train.

The smart textile market for sportswear hit $7 billion (€6.7 billion) in 2024 and is racing toward $89 billion (€85 billion) by 2035, driven by brands embedding electronic sensing and adaptive materials directly into athletic apparel.

A comprehensive review published Dec. 19 in the UK’s Royal Society of Chemistry Advances journal tracks the evolution from natural fibers through synthetics to today’s electronically enhanced fabrics. Analyzing hundreds of studies, the University of Georgia and Donghua University team provides a roadmap of material innovations and their practical applications for product development decisions.

The fabric revolution: from cotton to conductive polymers

Sportswear materials evolved through distinct technology waves. Cotton and wool ruled until mid-century, when nylon (1935) and polyester (1950s) brought step-change improvements in durability and moisture management. These synthetics became industry defaults, delivering lighter weight and better performance than anything natural fibers could offer.

The 1970s brought specialized performance fabrics. Spandex enabled form-fitting garments for gymnastics and track, while Gore-Tex introduced waterproof-breathable membranes for outdoor sports. By the 2000s, antimicrobial treatments and UV protection became standard finishing techniques.

When fabrics learned to think

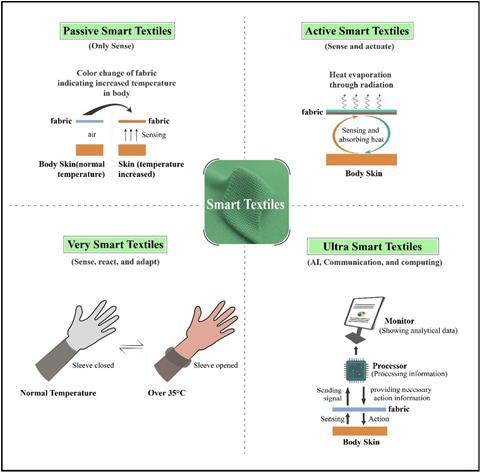

Smart textiles arrived in the 2010s, embedding electronic components directly into fabric structures. These materials sense environmental conditions, monitor physiological data, and adapt their properties in response to what’s happening. Think of it as three generations of intelligence. Passive smart textiles sense but don’t respond – moisture-sensitive fabrics that show sweat levels, or UV-reactive materials that shift color in sunlight.

Active smart textiles respond dynamically to stimuli. Shape-memory fibers adjust compression based on body movement, while thermo-responsive fabrics regulate insulation according to temperature changes.

Ultra-smart textiles pack in sensing, actuation, and data processing simultaneously. These garments detect heart rate, adjust thermal properties, and beam information to mobile devices all at once. Examples include Hexoskin shirts monitoring ECG and respiration, plus Catapult trackers woven into compression wear.

Every material choice involves trade-offs

Different material platforms excel at different jobs, and understanding these trade-offs matters for product development. Polyaniline-coated textiles deliver electrical conductivity for sensing and heating but wash poorly. Graphene-based fabrics provide adaptive thermal regulation through tunable infrared properties, though mid-range effectiveness remains limited.

Piezoelectric polymers like PVDF harvest energy from body motion to power wireless sensors. They’re flexible and valued for that, but low output and stability issues over time hold them back. Graphene systems beat PVDF textiles for thermal control but sacrifice flexibility – showing how material selection depends entirely on what the garment needs to do.

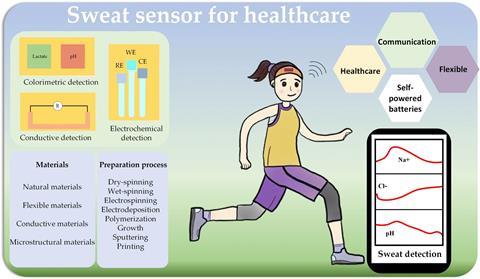

For biochemical monitoring, wearable sensors now analyze sweat composition in real-time. These systems measure glucose, lactate, sodium, and pH levels, delivering insights into hydration, metabolic state, and performance. The catch: they need robust power management and data processing infrastructure.

Where you put the sensor matters as much as the sensor itself

Sensor placement dramatically impacts data quality. Respiratory sensors work best on chest bands. Strain sensors demand precise positioning on joints or muscle groups. Get the placement wrong, and your expensive technology generates worthless data.

Moisture management fundamentals still apply, smart or not. Fabric structure drives performance: finer yarns and greater stitch lengths boost comfort in humid conditions by improving air and water vapor flow. Single-knit constructions excel for base layers thanks to superior softness and shape retention.

Thermoregulation varies wildly by material. Polyester fabrics showed notable core temperature drops during exercise compared to cotton in several studies, though results depend on testing conditions and workout intensity.

The compression clothing controversy

Evidence on compression garments tells a complicated story. Some research found improvements in force generation, sprint times, and jump height. Other studies? No measurable performance benefits whatsoever.

Biomechanical effects proved more consistent in swimming. Studies on competitive suits showed surface structure and coating treatments reduced water resistance and improved kinematics, though benefit magnitude varied.

Bottom line: compression garment effectiveness depends heavily on garment pressure, fabric construction, exercise type, and how you test it. Translation for brands: you need rigorous validation protocols before making performance claims.

The washing machine remains the enemy

Smart textiles face brutal practical challenges. Washability tops the list – repeated laundering damages electronic components and kills sensor function. Early products like the Philips-Levi ICD jacket made users remove all electronics before washing. Not exactly consumer-friendly.

Power supply constraints box in many applications. Conventional rechargeable batteries are bulky and nightmarish to integrate with textile architecture. Solar cells, flexible batteries, and energy-harvesting devices show promise but can’t touch traditional batteries for capacity and output.

Here’s the fundamental problem: textile and electronics industries run on completely different manufacturing processes, quality standards, and regulations. Successful products need multidisciplinary teams spanning textile science, polymer chemistry, physics, bioengineering, and software development.

The global technical textiles market hit $200 billion (€192 billion) in 2024, with sportswear driving major growth. But many smart textile applications remain stuck in research phases due to cost barriers and integration headaches.

Sustainability enters the equation

Since 2010, environmental impact has moved from afterthought to priority. Brands increasingly adopt recycled polyester, biodegradable materials, and eco-friendly dyeing in response to customer pressure.

Future smart textiles must balance performance with planet-friendliness. Next-generation garments will likely combine self-regulating features with responsible production methods, though specific pathways remain under development.

What actually works today

Current commercially available smart sportswear includes several proven technologies worth knowing about. Textile-based ECG electrodes embedded in shirts enable long-term heart monitoring during training. Piezoresistive fabric sensors knitted into garments detect movement patterns and posture.

The Biotex system integrates pH sensors, sweat rate monitors, conductivity sensors, and salt detection into a lower-back waistband, while chest bands incorporate pulse oximetry and respiration sensors. These platforms demonstrate feasible integration of multiple sensing modalities.

Optical fiber sensors woven into elastic belts provide highly accurate respiratory monitoring with minimal power requirements. Fiber-based temperature sensors using thermochromic materials detect body heat changes without external power.

Product development lessons from the data

Several evidence-based principles emerge for brands. Match sensor technology to specific metrics: capacitive strain sensors for movement tracking respond in under 30 milliseconds, while biochemical sensors deliver metabolic data but guzzle power.

Material selection should prioritize the dominant use case. Need thermal regulation? Graphene-based textiles beat energy-harvesting alternatives. Want physiological monitoring? Textile-integrated sensors enable more comprehensive data than wrist-worn devices, despite tougher manufacturing.

Fabric structure fundamentally affects comfort. Knit architecture, yarn density, and fiber type interact to determine thermal resistance, moisture transport, and how it feels against skin – parameters brands can systematically optimize through testing.

What we still don’t know

Several gaps need filling. Standardized testing protocols for smart textile performance don’t exist, making cross-study comparisons nearly impossible. Long-term durability data is scarce, particularly for novel materials.

Most research focuses on sensing and monitoring, with less attention to actuation and adaptive response. Energy harvesting looks promising but needs major improvements in power density and reliability.

AI integration with smart textiles represents the emerging frontier. AI-enabled systems could analyze physiological data in real-time and autonomously adjust garment properties, but practical implementations remain rare.

The growth curve ahead

Multiple market researchers project explosive expansion, with compound annual growth between 26 percent and 30 percent through 2035. North America leads now, though Asia-Pacific is catching up fast thanks to manufacturing capacity and government backing.

Sports and fitness captured the largest market share in 2024, driven by consumer appetite for performance monitoring and health tracking. Military and defense applications are surging, with governments pouring money into adaptive uniforms and personnel monitoring systems.

Smart textiles will transform sportswear through continued advances in materials science, miniaturized electronics, and data analytics. But success requires solving washability, power supply, cost, and standardization challenges first.

For sporting goods brands and retailers, this research provides essential knowledge as the industry shifts from passive performance fabrics to interactive, data-generating garment systems that fundamentally change what clothing can do.

Research methodology

The analysis examined studies published through January 2025, evaluating material properties, manufacturing techniques, performance testing, and commercial applications. The team synthesized findings from materials science, textile engineering, sports science, and electronics research for an interdisciplinary view of smart textile development.

“Advancements in functional smart and wearable textiles for sportswear applications” (https://doi.org/10.1039/D5RA07231J, Open Access) was published Dec. 19 in RSC Advances by Md Touhidul Islam, Md Imran Hosen, Tarikul Islam, Md. Abdullah Al Mamun, and Tariful Islam from the University of Georgia, Donghua University, and Mawlana Bhashani Science and Technology University.