Bangladesh is the second largest apparel exporter in the world, after China, according to the International Labour Organisation. In 2022, the apparel industry accounted for 82 percent of the country’s total export revenue, employing 4 million garment workers. But what, if anything, has been done to secure the welfare of these workers? To mark the ten-year anniversary of the Rana Plaza disaster, we look at what our industry can do to further the safety of its apparel workers.

What happened at Rana Plaza?

The eight-story Rana Plaza factory building, which employed around 5,000 people in Bangladesh, collapsed on April 24, 2013, killing more than 1,100 people and injuring 2,500 more.

It housed several textile companies, with clothes being made for international fashion companies such as Primark and Benetton. Vibrations from textile machines and a generator caused the illegally built upper floors to collapse.

Shortly before the collapse, several workers reportedly refused to enter the building because of safety concerns. According to reports, factory operators forced workers to return to their workstations despite cracks in the building and engineers declaring the building unsafe.

The tragedy caused international outrage and renewed calls to protect the workers providing the world with clothes; but ten years on, has anything really changed?

Rana Plaza: The ongoing impact on survivors

In a recent survey of Rana Plaza collapse survivors by ActionAid Bangladesh, nearly a quarter reported a decline in their health. More than a third of respondents have back pain, and a quarter have headaches. In terms of psychological health, among the 29 percent of “traumatized survivors” in 2023, more than half live in fear because of their experience of building collapse, and almost a third are tense about their health and safety.

Today, 54.5 percent of survivors are unemployed. Among them, 89 percent have been out of work for the last 5–8 years, suggesting ongoing challenges faced by survivors when finding and sustaining employment. The survey also found that the main reason for unemployment is “physical health conditions” (47 percent), with “mental health condition” cited by 10 percent.

Given these figures, there is also an economic disparity in the financial circumstances of many survivors. The ActionAid survey of 2023 found that the household income of the majority of respondents is insufficient to cover the family expenses (especially with the current cost of living increase).

Change is happening, but slowly

Also included in the results of the 2023 ActionAid follow-up survey of survivors is a section conducted with 200 current garment workers in Bangladesh to assess the safety situation in their factories. Like in Rana Plaza, most workers surveyed were women (84.6 percent).

These workers report a varied takeup of safety initiatives, with 31.8 percent of participants reporting management had taken initiatives only once in the last ten years. More than half surveyed felt that the frequency of initiatives taken was inadequate.

Safety hazards were also highlighted by 60 percent of respondents, including lack of health and safety or fire safety, insufficient air and lights, and machinery problems.

However, speaking to Nikkei Asia, Faruque Hassan, president of the Bangladesh Garment Manufacturers and Exporters Association, explained that after the Rana Plaza collapse, labor laws were amended and rules prepared to create a more pro-worker system. The publication reports that before Rana Plaza, there were only 74 registered trade unions in the garment industry; that number has increased to over 1,200.

The amended Bangladesh Labour Act of 2013 raised the need for safety committees to be established in factories with over 50 workers. To date, some 6,000 safety committees have been formed in garment factories and other economic sectors. A National Occupational Safety and Health Day is marked across Bangladesh on 28 April each year, and the Bangladeshi government now has a compensation scheme in place for injured workers or their families.

An international accord for health and safety in the textile and garment industry

Although not the first and definitely not the last disaster in the factories of the world’s apparel industry, the Rana Plaza collapse can be seen as somewhat of a turning point in the textile industry due to one key consequence: The establishment of a legally binding industry accord.

Following the building collapse, worldwide coverage called for international measures to improve the safety of garment workers in Bangladesh. The culture of fast fashion faced global condemnation. The Obama Administration even suspended trade benefits with Bangladesh for not doing enough to recognize workers’ rights in the country.

In May 2013, many companies, together with trade unions, signed the Bangladesh Accord on Health and Safety; now known as the Accord for Health and Safety in the Textile and Garment Industry, after its renewal in August 2021.

As of April 21, 2023, 197 international brands are now signed up to the legally binding agreement, including Adidas, Gymshark, Hanesbrands, Hummel, Intersport, Peak Performance, the Oberalp Group, and Puma.

The accord’s three goals aim to promote a culture of workplace safety, prevent fire, electrical and structural accidents, and allow workers to raise safety concerns. Company signatories to the International Accord commit to:

- Disclosing all factories producing for them in countries with International Accord programs.

- Ensuring all listed factories participate in the inspection, remediation, and safety training programs.

- Supporting factories to ensure remediation is financially feasible.

- Contributing to the operational costs of International Accord programs.

In a statement marking the tenth anniversary, the International Accord declared: “The Accord and RMG Sustainability Council (RSC), which carried forward Accord operations in Bangladesh since June 2020, have conducted nearly 56,000 fire, electrical, and building safety inspections at over 2,400 garment factories. Over 140,000 safety issues at these factories have been resolved, contributing to safer working conditions for workers.”

The next step is to improve working conditions in Pakistan: “While … efforts have borne tangible results in Bangladesh, the International Accord signatories have decided to extend these measures and learnings to Pakistan to ensure Pakistani textile and garment workers also have access to minimal health and safety measures including safe exits, fire alarm systems and workplaces with structural integrity.”

35 brands have signed the Pakistan Accord as of Feb. 2023, including Hummel. This is a good start, but it is not enough. For many organizations, the only real way to achieve change is via a fully transparent garment manufacturing industry; one in which consumers were fully aware of the conditions under which their garments were made and were happy with these conditions.

Achieving change through garment industry transparency

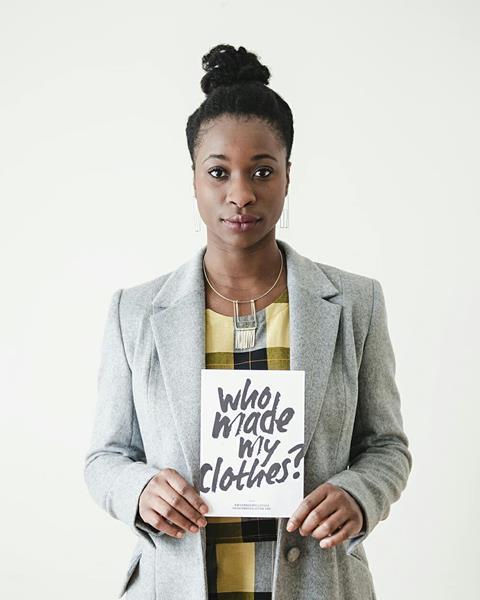

Fashion Revolution was founded by Carry Somers and Orsola de Castro in the wake of the Rana Plaza disaster in 2013 and now mobilizes brands as well as citizens and policymakers, to ensure that people (especially garment workers) are not favored over growth and profit. Among other efforts, they campaign chiefly for safer working conditions along the entire textile supply chain. This depends on a culture of transparency and accountability across the value chain.

In order to build this, every year, Fashion Revolution releases its Fashion Transparency Index. This reviews brands’ public disclosure on human rights and environmental issues across 246 indicators in 5 key areas. In 2022’s seventh edition, 250 of the world’s largest fashion brands were included, including brands from the outdoor and sporting apparel and footwear industry.

Whilst the report indicates that more brands than ever now publish a list of their first-tier manufacturers (48 percent), 50 percent of brands still do not disclose information about their supply chain. Most major brands and retailers do not publish the number of workers in their supply chain paid a living wage, and only 13 percent of brands disclose how many of their supplier facilities have trade unions.

In 2022, The North Face and Timberland both achieved a second-place score with 66 percent. (For reference, no brand achieved more than 80 percent). Puma was also included in the top ten scores of 2022, coming in with the seventh-highest score of 58 percent. At the bottom end of the scale were brands including Sports Direct, Skechers, and Canada Goose.

Columbia Sportswear was one of the brands to achieve the highest increase in scores since 2021, whereas Hanes, Patagonia, Helly Hansen, Speedo and Reebok all had some of the biggest decreases in scores.

While the Fashion Transparency Index does not evaluate the actual CSR work done by brands, by encouraging them to be more transparent, it is hoped this will have a knock-on effect of encouraging best practices.

What can sporting goods brands do to help after the Rana Plaza tragedy?

In order to continue to improve the welfare of first-tier manufacturers, all players must recognize that the safety of garment workers goes beyond building safety and also includes economic security (i.e. fair wages), compensation following work-related injuries, gender safety, and environmental protection.

Unionization is often touted as key. The top priorities of the International Labour Organization following Rana Plaza include further reform of labor laws in alignment with international standards and strengthened respect for trade unions. For brands, this means accepting that higher wages will push up manufacturing costs.

Ultimately, the responsibility to prevent another Rana Plaza disaster lies with many players: Citizens, policymakers, retailers, and of course, consumers. To increase consumer awareness, The Clean Clothes Campaign maintains a list of brands that have yet to sign up to the Accord, which includes Columbia and Decathlon.

For campaigners Fashion Revolution, there are three tangible actions brands and retailers can take to help improve the welfare of textile workers:

- Sign up to the International Accord.

- Sign up to the Pakistan Accord.

- Publish your supply chain right down to the raw material level as soon as possible, doing so in alignment with the open data standard and uploading the list to the Open Supply Hub.