A materials science startup is inverting traditional sportswear innovation. Instead of testing cooling fabrics on Himalayan peaks then filtering down, LifeLabs chose golf courses as its proving ground—solving problems in mass-participation sports rather than chasing extreme performance claims, says vice president Ben Ryan in conversation with Sporting Goods Intelligence Europe.

The conventional wisdom about technical sportswear innovation follows a predictable trajectory: test it in extreme conditions – Himalayan peaks, desert ultramarathons, polar expeditions – then gradually filter the breakthroughs down to everyday athletic wear, and further down into the streets life. LifeLabs is taking the opposite approach.

The materials science company, founded by Stanford Professor Yi Cui and CEO Sophia Ou, chose the golf course as the proving ground for its CoolLife cooling technology. Not because golf is extreme, but precisely because it isn’t.

“Finding ways to innovate in a way where it’s accessible for everybody to feel more comfortable or perform in sport, I think is the future,” said Ben Ryan, vice president and advisory board member at LifeLabs. “Democratizing comfort means that if you’re in a low intensity sport, let’s say golf, you still deserve to be brought back to comfort. You shouldn’t have to overheat and sweat before you can be comfortable.”

The golf opportunity

Golf’s cultural resurgence created the strategic opening. The sport is experiencing a demographic shift not only in the US – younger players, more women practicing regularly, broader participation, new formats – that’s reshaping product expectations. These newer golfers bring demands forged in athleisure and technical sportswear: performance that actually performs, comfort that’s engineered rather than accidental, sustainability that’s substantive rather than symbolic.

More critically, they’re playing in conditions that test fabric technology as rigorously as any alpine ascent. Four to five hours outdoors. Full sun exposure. Limited shade. Sustained moderate activity generating steady body heat without the sweat-management opportunity of high-intensity exercise.

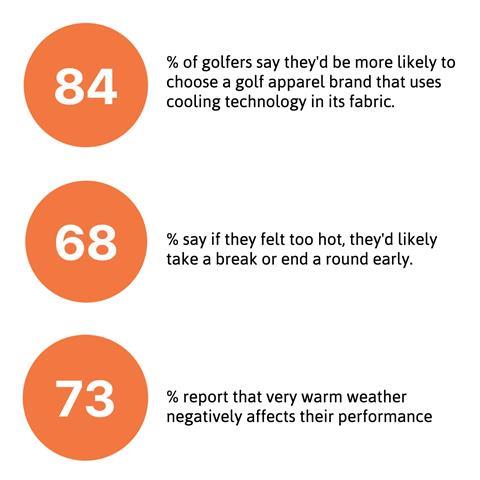

According to research LifeLabs commissioned from The Harris Poll in January 2026, heat creates measurable commercial friction. The study surveyed 2,096 US adults including 459 golfers and found that 68 percent of golfers say if they felt too hot while playing, they would likely take a break or end a round early. Seventy-three percent report that warm weather negatively affects their performance, with 22 percent citing major impact.

Perhaps most telling for sporting goods brands: 84 percent of golfers say they would be more likely to choose a golf apparel brand that uses cooling technology over one that does not.

“Golfers are clearly telling us that comfort and performance go hand-in-hand, and that heat can be the difference between finishing strong and cutting a round short,” said Mya Franklin, director of North America business operations at LifeLabs.

For a materials company looking to scale a cooling technology platform, these numbers represent proof that comfort innovation has commercial traction in mainstream sporting contexts.

The technology: continuous cooling without compromise

CoolLife’s technical approach differs fundamentally from existing cooling textiles. Traditional moisture-management fabrics rely on sweat to activate their cooling effect, essentially optimizing the body’s own thermal regulation system. They work, but only after you’ve already overheated enough to trigger perspiration.

CoolLife operates differently. The yarn is produced using globally patented nanoporous polyethylene polymer technology developed at Stanford. The fiber structure allows infrared radiation from the body to pass through the fabric rather than reflecting it back onto the skin – making it what LifeLabs calls the world’s first thermally transparent textile.

The practical result: a continuous cooling effect that reduces surface temperature by 2°C without requiring moisture, chemical treatments, or coatings that degrade over wash cycles.

“CoolLife isn’t a marketing buzzword – it’s a fabric performance platform that manages heat, enabling golfers to be comfortable for 9, 18 or 36 holes,” said Jordi Beneyto-Ferre, director of textile innovation and sustainability at LifeLabs. “Our goal is to work with brand partners to translate thermoregulating science into golf-ready materials balancing cooling comfort, breathability, and durability ensuring that performance doesn’t drop when temperatures rise.”

The technology’s permanence addresses one of sporting goods brands’ persistent frustrations with performance treatments: consumer disappointment when function fades. Because CoolLife’s cooling property is inherent to the fiber structure rather than applied as a finish, it doesn’t wash out or diminish over the product lifecycle.

Sustainability as structure, not supplement

The sustainability angle emerged not as marketing positioning but as native to the technology’s architecture. CoolLife yarn requires significantly lower energy and water inputs to produce compared to polyester, nylon, or cotton. According to the Material Sustainability Index, it delivers a more favorable environmental impact rating compared with conventional synthetic fibers, man-made fibers, and natural fibers.

More importantly for circular economy goals, CoolLife is recyclable and because there are no chemical treatments to degrade, performance remains consistent from first wear to last. This addresses a core challenge in technical sportswear: products that lose function become candidates for disposal even when the garment structure remains intact.

“With CoolLife intentionally, it’s a very fiber-focused technology that doesn’t require extra chemicals so they never wear off,” Ryan explained. “It performs the same on the first day that you buy it to the last day that you wear it. The performance will always be the same.”

The democratization strategy

Ryan’s background spans three decades across outdoor and sporting brands - including North Face, Arc’teryx and Salomon. That experience informed LifeLabs’ market entry logic: democratization.

Rather than following the traditional innovation pathway - equip elite athletes, then migrate to broader markets - LifeLabs designed for scalability from the start. CoolLife integrates into existing manufacturing processes and works within established supply chain partnerships. Brands can adopt the technology without overhauling their product development systems or sourcing relationships.

“You can have great technology, but can you actually get things made?” Ryan noted. “The supply chain is the other half of the problem.” That emphasis on manufacturable innovation reflects lessons from outdoor industry attempts to commercialize laboratory breakthroughs that couldn’t scale beyond limited releases. LifeLabs structured around preventing that outcome, pairing Professor Cui’s materials science research with Ou’s textile industry and brand partnership experience.

Golf serves as proof of concept for this democratization thesis. If cooling technology demonstrates consumer pull and commercial viability in a mass-participation sport with moderate performance demands, the platform can expand across active lifestyle categories – athleisure, everyday wear, work apparel – without requiring extreme conditions to justify the technology.

eLabs’ ambitions extend beyond managing heat. The company’s technology portfolio includes WarmLife, a heating based on the same research foundation as CoolLife. The vision: provide comfort solutions across temperature extremes, enabling people to spend more time outdoors regardless of conditions.

Ryan tested WarmLife at minus 35-40°C on Antarctica’s highest peak, establishing performance credibility at the extreme end while keeping everyday application in view. “We would like to think that no matter what the conditions are, we can make anybody more comfortable to enjoy life,” he said. “That can be in the office. It can be doing sport. It’s on every continent.”

The golf strategy reveals LifeLabs’ underlying commercial logic: build technology that works in ordinary conditions, not just extraordinary ones. Make it integrate seamlessly into existing manufacturing. Demonstrate measurable consumer demand. Then scale horizontally across categories where temperature regulation affects comfort and participation.

For sporting goods brands watching their younger consumers increasingly expect – and research before purchasing –this is genuine performance innovation married to sustainability credentials, LifeLabs’ approach offers a different calculus than the traditional outdoor-to-mainstream innovation funnel.

The question isn’t whether the technology works in extreme conditions. The question is whether it solves problems people actually experience in the sports and activities they actually do. For 68 percent of golfers who’ll cut a round short when overheated, CoolLife provides a clear answer.