The circular economy is currently one of the most promising solutions for the apparel industry to reduce its environmental footprint, with production, use and disposal taking place in a closed cycle of material flows. We look at what textile recycling is not (it may surprise you) and share some brands and recycling projects that are moving the outdoor and sporting goods industries in the right direction.

Garment-to-garment recycling is still in its infancy

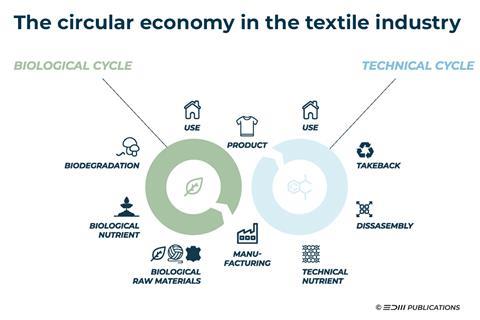

When we’re talking about a product’s end-of-life, a distinction is made between two cycles: The technical cycle, in which materials can ideally be recycled and reused again and again; and the biological cycle, in which biodegradable materials are converted into biomass.

So much for the theory. Because the textile industry has so far hardly progressed beyond project status in terms of practical implementation, especially in the technical cycle, which is particularly relevant for the outdoor and sporting goods industries. According to the Ellen MacArthur Foundation, just 13 percent of the world’s textile waste is currently recycled, and this is mainly for low-quality applications such as upholstery, insulation or cleaning rags. The remaining 87 percent is destined for landfill or incineration.

True garment-to-garment recycling is still in its infancy. Yes, many outdoor products use recycled materials. However, this is mainly recycled PET, mostly obtained from plastic bottles. And this does not solve the clothing industry’s own waste problem, the extent of which has become increasingly clear in recent years.

In addition, the use of recycled materials does not say anything about whether the product made from them is, itself, recyclable at end-of-life – an essential criterion of circularity. Looking again at the example of recycled PET, once processed into a garment, the materials from recycled bottles usually end up in a dead end. “Re-recycling” is not possible, as the individual material types of the garment must be separated from each other before recycling. This is still far too expensive at the moment.

Not a subscriber yet?

Dive deeper into the sporting goods industry with the latest insights and stories – straight to your inbox!

Using recycled PET for textiles is not recycling

Celebrated as an innovation just a few years ago, PET recycling from bottles is now viewed more critically. Environmental associations such as the NGO Surfrider Foundation and consumer advocates have also long suspected greenwashing behind PET recycling in the clothing industry.

In response, Ortovox recently declared its intention to dispense with recycled polyester from bottles in the future. In its annual Planet Report 2023, the company describes this type of recycling as too short-sighted. Instead: “We want to take responsibility, be a pioneer, and recycle the products that we and the apparel industry put into circulation. We are, therefore, deliberately taking the more difficult path in order to develop leverage that will last in the long term,” said Christine Brien, Head of Material at Ortovox.

With these realizations, investments in new recycling technologies are increasing and new collaborations are emerging between materials research companies, textile producers, brands and recycling companies. More and more companies are embarking on the uncomfortable path and looking for new solutions. In the process, more and more products are being created that have real potential for textile-to-textile recycling.

3 genuine ways to promote textile-to-textile recycling: Mono-material, post-consumer recycling and biodegradable products

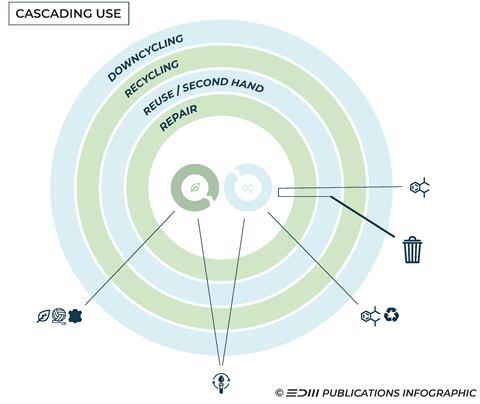

There are different approaches to the topic of circular economy. The first is to focus on the “cascading” of products over as long a period as possible, by using materials that create the most economic value over multiple lifetimes.

Outdoor and sporting brands can boost circularity with respect to recycling, by developing products made of mono-material, such as Jack Wolfskin with the Bike Commute Mono Jacket, Haglöfs with the Roc Mono Proof Jacket or Schöffel with the Circ Pants Loop. These products are made of only one material, polyester, which also includes zippers, membrane and other components, and can therefore be recycled.

According to Schöffel, 97 percent of the polyester used in the Looop trousers can be reused. At Haglöfs, the zippers and waterproof tapes must be mechanically removed before recycling. But even for this hurdle, there are already ideas for implementation. Decathlon, for example, alongside the company Resortecs has developed a ski jacket whose sewing thread melts at temperatures above 190 degrees, which makes it easier to separate different materials in the recycling process.

A second way to boost textile recycling is to focus on the raw materials that are already in circulation, tackling the waste problem of the textile industry. More and more brands are seriously involved in post-consumer recycling and are developing their first products as well as the necessary technologies and processes.

For example, Puma has its Re:Jersey project, through which old football jerseys made of polyester from all manufacturers are collected and recycled. “The technology, which is based on the chemical depolymerization and repolymerization of polyester, has actually been around for over ten years, but has only now become affordable,” explains Puma’s Chief Sourcing Officer Anne-Laure Descours. By 2030, Puma wants to use only polyester from used clothes. At Jack Wolfskin, too, the outer material of eleven styles in the 2024 summer collection is made from recycled textile material.

The circular economy has even arrived at socks. In 2021, Smartwool launched a take-back campaign, the Second Cut Project, collecting used socks of all types and brands from retailers and online to use for dog bed filling. This was expanded in 2023 to include resale of Smartwool socks, and now turns old socks into new ones with the Second Cut hiking sock. The yarn for this model consists of 33 percent of the company’s own sock take-back program and production waste, blended with new merino wool and partially recycled synthetic fibers.

The biological cycle also plays an important role in the sports and outdoor industry, and will probably become increasingly important in the future. Not because natural fibers such as cotton and wool convert to biomass at the end of the product life cycle; but because, thanks to new material developments, synthetic materials used in performance clothing are also increasingly bio-based or biodegradable.

Last year, Kathmandu unveiled the NXT-Level Bio Down Jacket, the first biodegradable insulation jacket made exclusively from biodegradable materials. Here, too, all components such as zippers, sewing threads, filling, etc., are biodegradable. In this way, too, the industry can make a contribution to reducing textile waste, at least in the long term.

Recycling footwear: First solutions are being tested

When it comes to Footwear, recycling still has many hurdles to overcome. According to the World Footwear Yearbook, 24.3 billion pairs of shoes were produced worldwide in 2019, most of which will one day end up in landfills, incinerators or second-hand markets in the Global South. This is because there is not yet a feasible recycling concept for shoes.

A shoe can consist of up to 30 components that are firmly connected to each other for durability, which is why shoe recycling has long been considered too complex. It was only in July that a new Fashion for Good pilot project was launched with brand partners Adidas, Inditex, Target and Zalando as well as shoe recycling innovator FastFeetGrinded to test and validate the shoe recycling process and promote the proportion of recycled content in shoes.

One Footwear category is leading the way in recycling

Although shoes have so far proven extremely difficult to recycle, the Sneaker industry is a pioneer in shoe recycling. Back in 2019, Adidas launched the Futurecraft.Loop, the first recyclable running shoe. At the end of 2019, Salomon presented its Index.01 concept shoe, which was made entirely of thermoplastic polyurethane (TPU) and actually launched two years later.

On’s Cyclon running shoe, which launched in 2021 via a subscription model, also caused a sensation. According to On, up to ten to fifteen recycling cycles per shoe should be possible. Just last month, Nike launched the ISPA Link Axis, according to Nike, its “first attempt to develop a fully circular shoe.” The design of the Link Axis consists of interlocking components, made using as few materials as possible, and without glue. As such, the shoe should be easy to disassemble and then completely recycle.

Ski boots and mountain boots making first steps into recycling

When it comes to ski boots, the industry has already developed solutions, with one brand leading the way. Through its Recycle Your Boots program, in which Tecnica has collected used ski boots of all brands, Tecnica has been able to gain insights into what complicates the recycling process and which materials cannot be recycled. The knowledge gained from this has been incorporated into the brand’s new Cochise model, which has been revised for the FW 23/24 season. Since last winter, all Tecnica ski boots have also been printed with a QR code that provides information about the materials used and is intended to facilitate recycling.

The circular economy is still much more difficult for classic leather shoes and mountain boots. But here, too, the first steps are being made. In April of this year, for example, Scarpa launched the Life Re-Shoes project: A recycling initiative supported by the European Union. The goal is to collect around 15,000 used Scarpa Mojito shoes by the end of the year to be recycled. The recovered material will be used to create new shoes that use between 50 and 70 percent recycled material, according to the company’s forecast.

Up next: Exploring the financial benefits of textile-to-textile recycling

If you have been inspired by these examples, our expert in sustainable fashion and circular design Amy Rauen, outlines the potential financial benefits of textile recycling for brands and 5 ways brands can drive textile recycling progress too.

Topics

- Adidas

- Circular Economy

- Circular Economy

- Circularity

- CSR & Sustainability

- Cyclon

- Decathlon

- Fashion for Good

- FastFeetGrinded

- footwear

- Haglöfs

- Jack Wolfskin

- Kathmandu

- Nike

- Nike ISPA Link Axis

- On Running

- Ortovox

- Outdoor

- Puma

- Re:Jersey

- Re:Thinking Business

- Recycle Your Boots

- Recycling

- Resortecs

- Salomon

- Scarpa

- Schöffel

- SGI Original

- Smartwool

- Surfrider Foundation

- Tecnica

- Textile Industry

- Textile waste